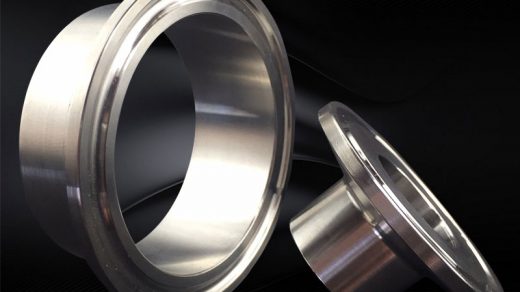

The pressure of sanitary fittings is an important parameter in the purchase of users’ selection. Stainless steel 201 and 304 sanitary tube pressure difference is: in terms of pressure, 201 stainless steel is higher. This is because 201 stainless steel has high manganese content as well as carbon. These two determine the strength of the alloy, so the mechanical properties of 304 stainless steel is good. However, the corrosion resistance of 304 stainless steel is higher than 201 stainless steel at two grades, and there is stainless steel 301 in the middle. Pressure capacity depends only on the wall thickness of sanitary fittings.

201 steel yield point is 275MPa, with tensile strength higher than 520MPa of 40% elongation. And 304 steel yield point is 205MPa, with anti-resistance strength higher than 515Mpa of 40% elongation. The yield strength of these two materials is not the same. For pipes, it is possible to use the method of calculating the thin-wall cylinder pressure vessel: P*D/2δ<σt.

In this formula, p is the tube internal pressure, D is the tube diameter, δ is the tube wall thickness, and σt is the permissible stress at the design temperature. For example, if the permissible stress and wall thickness of the two materials are not the same, then the pressure is not the same. If the same wall thickness equals, 304 sanitary tube can withstand greater pressure.

Recent Comments