Sanitary fittings are components that are assembled to create clean pipelines that are used to transport products and fluids. Fittings are used in the pharmaceutical, biotech, beverage, diary, food and other industries. These components are designed to allow the passage of materials, including solid products, without clogging the system.

There are many health components that are used in many industries to allow products to pass. Some of these components include tri-pliers, beveled seats, butt welds, sanitary collars, sanitary DINs and I-line. These fittings are available in many materials and qualities. These include stainless steel, polyethylene, polypropylene, PVDF and many other materials that provide high hygiene standards.

Fittings are also available in many finishes. These adhere to specification industry standards based on their location. Some examples include USDA, FDA BPE and SSF4.

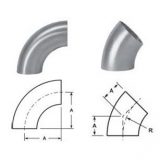

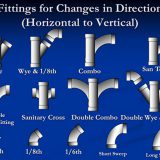

Sanitary fittings are manufactured in many configurations. These include eccentric reducers, concentric reducers, end caps, pliers, tees, elbows, adapters and end caps. High quality fittings are available for almost any situation.

Stainless Steel Sanitary Fittings – These include fittings such as brackets, indicators, ports and sanitary fittings designed to increase sanitation levels. They aim to ensure that the hygiene, the cleanliness of the joints and the ease with which the flows of materials are maintained to the expected standards. Industries where such standards could be of such importance include the brewery industry.

Sanitary Clamp Fittings – These fittings and accessories are specifically designed for industries where clean joints and efficient flow of materials are essential. These include the biotechnology and pharmaceutical industries. Stainless steel has desirable qualities over currently available hose clamps. In addition to its faster access and easier cleaning ability, stainless steel fittings are preferred because of their lower costs.

Garolla Fittings – The Italian equivalent of a tri-tong is called Garolla. Because this fitting is made of 304 stainless steel, it guarantees high quality performance. In its design, the ferrule of the Garolla is tapered in a way that makes its sizing not apparent as it is the case with a tri-clamp. The Garolla has unique dimensions. These fittings can be found on some Italian equipment. It is important to know which components fit well with your equipment. Tri-clamp and Garolla can not be used interchangeably.

Recent Comments