The advantages and disadvantages of V-ball valves and double-seated control valves

Double-seated control valve because of the upper and lower two seats, so the unbalanced force is small, suitable for the pressure difference is relatively large, the request for leakage volume is not high, equal caliber double-seated control valve can also be a little smaller actuator standard requirements; but double-seated control valve flow path is chaotic, the activity of resistance, adjustable scale is small; valve stem up and down movement, spool stability is poor, oscillation is large.

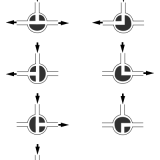

Compared with the straight-stroke double-seated control valve, the V-type stainless steel ball valve has great advantages, these advantages are determined by the structure of the V-type ball valve. v-type ball valve spool in the structure of the selection of the pain structure, in addition to the closed position, the core seat does not touch the rest of the position, reducing the wear and tear, once the spool is turned off the seat, reducing the operating torque. The V-shaped opening on the spool can ensure the valve’s adjustment performance in small openings, dealing with the problem of poor operating characteristics of direct stroke valves in small openings.

V-type ball valve flow path is simple, single straight type, small resistance to activity, adjustable scale, flow open valve pressure recovery coefficient is higher than the double-seated valve, more suitable for the onset of cavitation conditions.

V-type ball valve spool, stem movement for rolling, and linear motion of the valve, compared with the valve, can overcome the pressure difference is large, is 2.5 to 10 times the direct stroke valve.

In dealing with high-temperature problems, V ball valves use the rigid-flexible elastic hard seal to deal with high-temperature expansion caused by the core seat holding, card problems adjustment, V ball valves, and double-seated adjustment valve advantages and disadvantages together with the use of high-temperature wear-resistant packing to ensure the reliability of the stem seal at high temperatures.

Recent Comments