How to select sanitary valves?

Sanitary valves used in water supply pipes are generally selected according to the following principles:

1, when the diameter of the pipe is not greater than 50mm, the cut-off valve, gate valves, and butterfly valves should be adopted.

2, we need to adjust the flow rate and hydraulic pressure, sanitary regulating valve and globe valve should be adopted.

3, where the flow resistance is small, gate valves should be adopted.

4, the flow should be two-way flow pipe segment, gate valve and butterfly valve should be used.

5, installation of small space parts should be used butterfly valve and ball valve.

6, in the frequent opening and closing of the pipe section, the cut-off valve should be adopted.

7, the larger diameter of the pump outlet pipe, should be multi-functional valve should be used.

What are the advantages of various valves?

1. Gate valve: Gate valve refers to the closing parts along the vertical direction of the channel axis moving valve, in the pipeline mainly as a cut-off medium, that is, all open or all closed use. Generally, gate valves cannot be used as regulating flow. It can be applied to low-temperature pressure, can also be applied to high temperature and high pressure, and according to the valve’s different material. But gate valves are generally not used for pipes conveying mud and other media.

Advantages:

1) Low fluid resistance;

2) The small torque required for opening and closing;

3) It can be used in the ring network pipeline where the medium flows are in two directions, that is, the flow direction of the medium is not restricted;

4) When fully opened, the sealing surface is less eroded by the working medium than the globe valve; the shape structure is relatively simple, and the manufacturing process is better; the length is shorter.

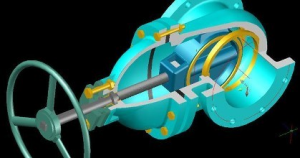

2. Sanitary butterfly valve: The butterfly valve is a kind of valve which opens, closes and adjusts the fluid passage by using the disc type open and close parts to and fro rotate about 90 degrees.

Advantages: 1) simple structure, small volume, light weight, consumable materials, used in large diameter valves; 2) open and close quickly, flow resistance is small; 3) can be used for suspended solid particles media, according to the strength of the sealing surface can also be used for powder and granular media. It can be used for two-way opening and closing of ventilation and dust removal pipeline, and is widely used in gas pipeline and water channel of metallurgy, light industry, electric power, and petrochemical system.

3. Sanitary ball valve: It is evolved from the plug valve. Its opening and closing parts are a sphere. The sphere is rotated 90 degrees around the axis of the stem to realize the purpose of opening and closing. The ball valve is mainly used to cut off, distribute and change the flow direction of the medium in the pipeline. The V-shaped open ball valve also has good flow regulation function.

Advantages:

1) Having the lowest flow resistance;

2) Not being stuck at work, so it can be reliably applied to corrosive media and low boiling point liquids;

3) Being able to achieve complete sealing in a larger range of pressure and temperature;

4) being able to achieve rapid opening and closing, and the opening and closing time of some structures is only 0.05-0.1s to ensure that they can be used in test benches and the automation system. When the valve is opened and closed fast, the operation is not affected. Spherical closure can be positioned automatically at the boundary position; Working medium is sealed reliably on both sides; When the ball and the valve seat are fully opened and closed, the sealing surface is isolated from the medium, so the medium passing through the valve at high speed will not cause the erosion of the sealing surface; Compact structure, lightweight, it can be considered to be used in low-temperature medium. The most reasonable valve structure of the quality system; valve body symmetry, especially the welding valve body structure, can withstand the stress from the pipeline; closing parts can withstand the high-pressure difference when closed. Fully welded ball valve body can be directly buried underground so that the valve internals are not eroded, the maximum service life of up to 30 years, is the best oil and gas pipeline valve.

4, Sanitary globe valve: the valve that closes along the centerline of the valve seat. According to the moving form of the disc, the change of the valve seat opening is proportional to the valve stroke. Because the stem opening or closing stroke of this kind of valve is relatively short, and has a very reliable cut-off function, and because the change of seat opening is proportional to the disc stroke, it is very suitable for flow regulation. Therefore, this type of valve is very cooperative to cut off or regulate and throttling.

Advantages:

1. In the process of opening and closing, the friction between the disc and the sealing surface of the valve body is smaller than that of the gate valve, so it is wear-resistant.

2. The opening height is generally only 1/4 of the seat passage, so it is much smaller than the gate valve;

3. There is usually only one sealing surface on the valve body and disc, so the manufacturing process is better and easy to maintain.

4. Because its filler is generally a mixture of asbestos and graphite, the temperature resistance grade is higher. General steam valves are globe valves.

5. Sanitary check valve: These valves are automatically opened and closed by the force generated by the flow of the medium itself in the pipeline, belonging to an automatic valve. Check valves are used in pipeline systems. Their main functions are to prevent medium backflow, pump and drive motor reversal, and container media release. Check valves can also be used to supply lines in which the pressure may rise to an auxiliary system that exceeds the system pressure. It can be divided into swing type and lifting type.

Recent Comments