Sanitary diaphragm valve shell test

1) Test medium: The following test media manufacturer can choose one: water. Allow containing corrosion inhibitor. Kerosene and other liquids with a viscosity are not greater than water, steam, air or other suitable gas. (When testing with steam, air or other gases, the test procedure shall be subject to approval by various legislative authorities).

2) Before the test, the sanitary diaphragm valve can be removed and can not withstand the test pressure of the inner parts.

3) With the liquid test, the trap should be the air within the net.

4) Prior to the shell test, the sanitary diaphragm valve shall not be painted or any material which may impede the leakage of the seal, but shall be resistant to chemical corrosion and internal lining. If the buyer requests a pressure test in the field, the storage has been painted and painted traps can dare to test without having to remove the coating.

5) Testing set peers should not be subjected to diaphragm valve test results bear the external pressure.

Sanitary diaphragm valve test system

The test system is very professional.

1) Test section

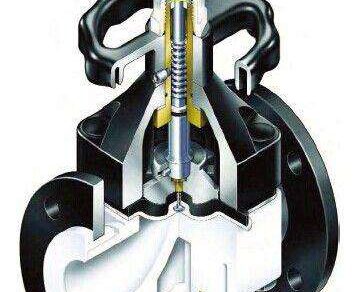

Connecting test sanitary diaphragm valve before and after the pipeline, its diameter should be consistent with the nominal size of the test valve. The figure provides the visual length of the pipe.

2) Back pressure device

It ensured that the valve has sufficient pressure and prevent cavitation.

3) Flow meter

The flow rate of a valve or pipe can be measured with a rotary, or with a calibrated vessel.

4) Pressure measurement device

It determines pressure loss.

5) Take pressure hole

The pressure on the pipeline to measure the hole, take pressure hole center line should be perpendicular to the pipe axis and in horizontal position. The cross-section shall be rounded and its edges shall be clean, sharp, free burrs, without linear edges or other irregular shapes. Its aperture should be equal to or less than 0.1d, but not less than 1mm, the largest is not more than 12 mm. The cross-sectional area of the pipe connecting the differential pressure measuring device is not less than half of the area of the pressure-receiving hole.

6) Thermometer

The temperature of the water is measured with a temperature sensor or a mercury thermometer.

Recent Comments